Our industrial electrolysers

Start your energy transition with reliable, efficient, and competitive electrolysers.

The M range is based on Bulane’s patented technology to optimize the hybridization of your burners.

- Compatible with your existing installations

- Flexible: partial or total substitution of fossil fuels

- High performance: precise control of H2/Gas/O2 mixing and flame quality

Combined with our EMS (Energy Management System), your energy mix adapts in real time to the costs and carbon content of electricity and gas. Result: maximized efficiency, greater competitiveness, and immediate carbon reduction.

5 electrolysers in this range

A range adapted to

The P range of alkaline or PEM electrolysers ensures continuous availability of perfectly separated hydrogen and oxygen, delivered directly at the required pressure (5, 10, 15, or 30 bar).

For the most demanding applications, an integrated purification option guarantees purity up to 5 ppm (99.9995%).

Fully autonomous, our stations can be remotely monitored and controlled, ensuring real-time tracking and maximum reliability.

32 electrolysers in this range

O₂ production: 0.25 Nm³/h to 100 Nm³/h

A range adapted to

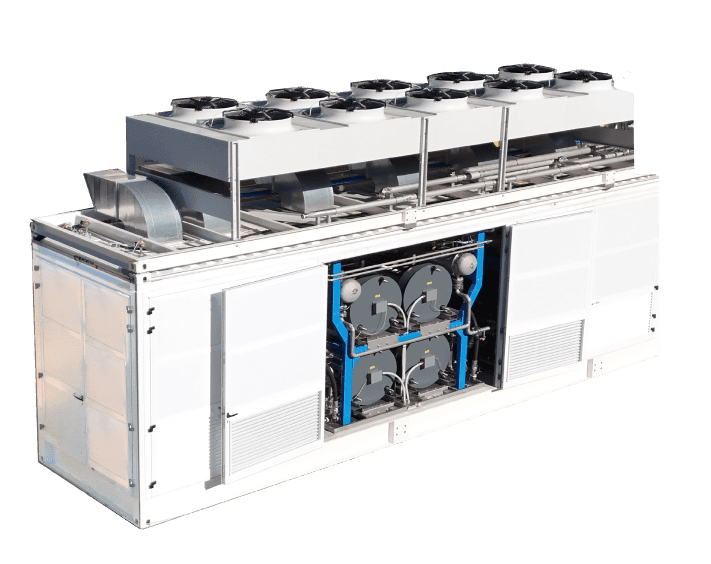

The MW range designed for the most demanding industrial processes, our MW electrolysers combine proven robustness with “All-In” engineering: each multi-stack unit is fully integrated, tested, and qualified in our factory — ready to produce from day one.

Thanks to their modular and controllable architecture, our systems deliver unmatched operational flexibility, high efficiency under any load, and simplified maintenance.

Manufactured in Europe / France, they include the complete Balance of Plant for rapid deployment and maximum reliability.

MW Electrolyser

O2 Production > 100 Nm3/h

A range adapted to

The L range offers an optimized solution for laboratory and test bench applications. Based on PEM technology with integrated purification, it delivers ultra-pure hydrogen (>99.9999%), ideal for scientific and educational uses.

Reliable and easy to use, these portable generators operate solely with double-distilled water and electricity, requiring no maintenance. Their secure design (leak self-diagnosis) ensures easy integration into any environment, with the option of parallel connection.

10 electrolysers in this range

A range adapted to

Why self-produce?

Evolve without revolutionizing

Our electrolysers powering our solutions

3 application solutions

The industries concerned

The applications covered

Understanding how our electrolysers work

This electrolysis technology transforms water into hydrogen and oxygen using electricity, providing companies with sustainable energy autonomy.

The electrolysis process works as follows: electricity passes through an electrolyte to separate water molecules (H₂O) into hydrogen (H₂) and oxygen (O₂). Combined with integrated treatment units, this reaction produces high-purity gas suitable for the most demanding industrial applications.

Electrolysis technologies: alkaline and PEM

Our alkaline electrolysers

Discover our alkaline electrolysers

Our PEM electrolyzers

Discover our PEM electrolysers

Where are our electrolysers used?

Our Dyoflam and Dyomix solutions are used, respectively, for oxy-flame applications, industrial thermal processes, and building heating.

Our Dyopure solution, on the other hand, meets the needs of processes using “material hydrogen.”

Meeting environmental regulations

Transitioning to low-carbon hydrogen via industrial electrolysis significantly reduces CO₂ emissions.

Industry is a key sector in the fight against climate change, generating 18% of national CO₂ equivalent emissions, with industrial combustion accounting for 92% of those. To meet this challenge, the sector must undergo profound transformation to decarbonize its activities.

The French National Low Carbon Strategy (SNBC) sets ambitious targets:

- 35% reduction in emissions by 2030 compared to 2015 levels

- 81% reduction by 2050

These goals drive industries to seek sustainable alternatives to fossil fuels. The low-carbon hydrogen self-production we offer directly supports these carbon neutrality objectives.

*Source: Alliance Allice public summary on the potential integration of decarbonized gases in industry

Sizing and technical specifications

System integration

Adaptable pressure, purity, and flow rates

From technical study to operation

Bulane supports you from the needs assessment through commissioning, operation, and maintenance of your industrial electrolyzers.

Our pre-sales team designs the best solution for your specific challenges:

- Replacing your delivered carbon-based hydrogen:

An opportunity study is conducted to determine a self-production solution that secures your supply of technical gas. - Decarbonizing your thermal processes:

A feasibility study is carried out to develop a self-production solution that allows you to flexibly manage your energy mix by hybridizing your production line. - Decarbonizing your oxy-flame applications:

A technical analysis of your needs helps define the efficient integration of our self-production solution into your oxy-flame processes.

Our technical team carries out the detailed execution study:

During this phase, depending on the solution being considered, technical studies or audits may be conducted on your existing processes.

Together with our teams and partners, we manage and monitor all project works.

Our priority is to control costs and the overall project schedule. Once implementation is complete, we ensure the commissioning of hydrogen and auxiliary equipment and verify their performance on your site.

Our after-sales service (SAV) team supports you throughout the entire lifecycle of your industrial electrolyzers:

We handle the transfer of operations and process monitoring, remaining available for after-sales support. Our qualified technicians are ready to carry out preventive and corrective maintenance operations.