PEM Electrolyzers

Technical Features of PEM Electrolyzers

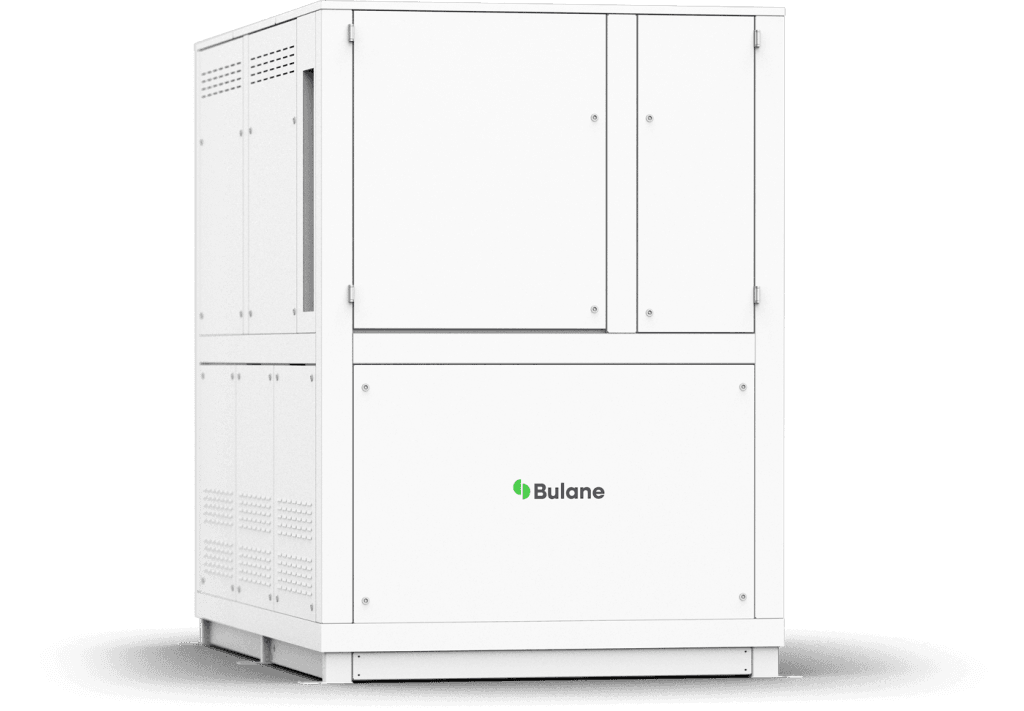

Compact, modular, and reliable, these gas generators integrate easily into 24/7 industrial processes or local hydrogen mobility projects.

A Turnkey System

Combining high gas purity with a Plug & Play system ensures maximum efficiency, ease of use, and optimal performance for decentralized energy or industrial applications.

Hydrogen Purity

Oxygen Purity

Output Pressure

Our Electrolyzer Ranges

Our PEM electrolyzers are part of the P and M ranges and can be used in the design of our Dyoflam, Dyomix, or Dyopure solutions.

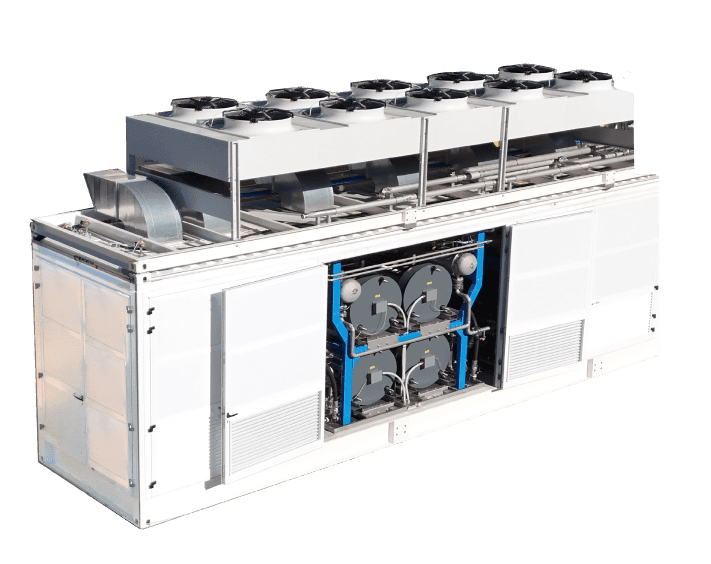

Components of a Complete PEM Electrolysis System

Our industrial P-range PEM electrolyzers are turnkey systems, including all necessary process auxiliaries:

Standard components in all systems:

- Electrolytic stack(s): The core of the reaction where hydrogen and oxygen are produced via water electrolysis.

- Electrical transformer: Converts AC to DC (low or medium voltage).

- Power supply unit: Controls and delivers current/voltage via three-phase power rectifier fully controlled by SCR.

- Control unit: Control panel and HMI interface.

- Primary and secondary cooling units: Cool the electrolytic stacks and condense produced gases (ensuring a minimum standard purity of 99.5%).

- Communication module: Modbus (standard).

Optional integrations:

- High-purity gas unit: Integrates a de-oxygenation and/or drying system to remove residual O₂ and H₂O from produced hydrogen.

- Process water purification unit: Integrates a reverse osmosis demineralizer.

- Gas analyzers and meters: Precisely monitor quality and adjust technical gas consumption.

Modularity and Containerization of Our Systems

All PEM electrolyzers can be installed with auxiliary equipment in 20- or 40-foot containers for outdoor installation. They are designed to be connected in parallel and controlled via a centralized control unit.

- Modular: Each 1 MW electrolyzer module contains eight 125 kW stacks operating in pairs. This modularity allows hydrogen production to adapt to customer demand or variable electricity availability (e.g., from renewable sources). It also allows safe expansion of production down to below 10% of nominal flow, exceeding the usual limit of 20–25% for standard electrolyzers. The cooling system is also modular, with a unit equipped with 10 fans powered in pairs, optimizing efficiency, reducing consumption, and ensuring a safe, autonomous, and controlled process.

- Turnkey: Each 1 MW module is contained in a 40-foot container designed for outdoor installation, including all necessary process auxiliaries (water demineralization, gas purification, gas analyzers, communication module, integrated nitrogen generator for safety, rooftop cooling systems). Each container also includes a dedicated external transformer/rectifier.

- Hydrogen Purification: An optional purification system ensures hydrogen purity above 99.9995% (O₂ < 5 ppm, dew point < -70°C), ideal for demanding industrial applications. The process includes de-oxygenation and drying steps to guarantee pure and dry gas.

- Control System: Fully integrated and isolated system section, including an electrical cabinet with PLC and touchscreen HMI for automatic process control, optimizing every step of hydrogen production. SRC 250 kW VAC/VDC converters provide stable, precise power to the electrolytic cells, with advanced modularity ensuring flexibility and reliability.

- Remote Assistance: The control unit manages all electrolyzer modules. Our self-production plants can be remotely monitored and diagnosed in real-time anywhere in the world via internet-based support.

Spécifications de nos électrolyseurs PEM

- L’industrie : clé en main et robuste de 1 à 1000 Nm3/h d’hydrogène (de 4kW à 5000kW en puissance d’électrolyse).

- Aux laboratoires et concepteurs de technologies H2 : : compact, modulaire, parfait pour des essais en laboratoire ou de technologie hydrogène de 0,15 NL/min à 8,3 NL/min (de 100W à 1500W).

Specifications of Our PEM Electrolyzers

Bulane PEM electrolyzers serve:

- Industry: turnkey, robust, producing 1 to 1000 Nm³/h of hydrogen (4 kW to 5000 kW electrolysis power).

- Laboratories and H₂ technology developers: compact, modular, ideal for laboratory tests or hydrogen technology, from 0.15 NL/min to 8.3 NL/min (100 W to 1500 W).

Industrial PEM Electrolyzer Specifications:

| Model | P4-PEM | P6-PEM | P7-PEM | P8-PEM | P9-PEM | P10-PEM | P12-PEM | P25-PEM | P50-PEM | P75-PEM | P100-PEM | P150-PEM | P250-PEM | P500-PEM | P1000-PEM |

| H₂ Production (Nm³/h) | 0,625 | 0,93 | 1,25 | 1,55 | 1,85 | 2,2 | 2,5 | 5 | 10 | 15 | 20 | 30 | 50 | 100 | 200 |

| O₂ Production (Nm³/h) | 0,3125 | 0,465 | 0,625 | 0,775 | 0,925 | 1,1 | 1,25 | 2,5 | 5 | 7,5 | 10 | 15 | 25 | 50 | 100 |

| Power (kW) | 4,5 | 5,6 | 7,0 | 8,0 | 9,6 | 10,2 | 11,5 | 25 | 50 | 75 | 100 | 150 | 250 | 500 | 1000 |

| Pressure (bar) | 15/30 | ||||||||||||||

| H₂ Purity | From 99,99% to > 99,9995% (with a dew point down to -70°c) | ||||||||||||||

| O₂ Purity | > 99% | ||||||||||||||

| Demineralized Water (L/h) | 0,4 | 0,6 | 0,9 | 1,1 | 1,3 | 1,5 | 1,8 | 4,1 | 8,3 | 12,6 | 16,9 | 26,1 | 43,5 | 90,0 | 180,0 |

| Dimensions (mm) | 700 x 830 x 1700 | 900x1900x2015 | 2805x1800x2280 | Conteneur 40′ 12192X 2438X 1800 | |||||||||||

| Weight (kg) | 300 | 305 | 310 | 340 | 345 | 350 | 355 | 1100 | 1300 | 1600 | 2000 | 3000 | 4000 | > 28000 | |

Applications of Our PEM Electrolyzers

Hydrogen produced by our PEM electrolyzers is used across multiple industrial sectors (metallurgy, chemistry, food industry, etc.) and for numerous applications, either as process gas or as a low-carbon fuel replacing fossil fuels in thermal, industrial, or building heating applications.

It is also used as an energy vector for heavy mobility and decentralized energy uses.

Benefits of Our Modular Electrolyzer Range

Compliance

Designed and manufactured according to current European regulations, CE marked, including:

- 2004/30/EU electromagnetic compatibility

- 2006/42/EC machinery directive / EN60204-1 electrical safety

- 2014/68/EU PED directive, electrical equipment safety

Reliability & Technical Support

Autonomous and remotely monitored electrolyzers require minimal daily intervention, only periodic preventive maintenance. All systems feature remote monitoring via teleassistance.

Autonomy

On-site, on-demand production ensures secure and cost-controlled industrial gas supply.

Safety

Reduces or eliminates stored gas volumes, minimizing associated risks and regulatory burdens.

Sustainability

Local production using low-carbon electricity (renewables, nuclear) significantly reduces the carbon footprint, including transportation and storage emissions.

Remote Operation

Hydrogen and oxygen production is fully automatic and can be remotely controlled.